Innovation and advancement in metal casting has been a driving force for many industries, from aerospace to construction. Over the years, advancements have made this process more efficient and reliable while also increasing its capabilities.

This article will explore the latest innovations that are changing the face of metal casting, ranging from improved materials to enhanced processes. It will also discuss how these advances are enabling new horizons in production and design possibilities beyond what was previously thought possible.

By examining these developments we can better understand why metal casting continues to be a vital tool for industry today.

Improved Casting Techniques and Processes

Metal casting is a process that has been used since ancient times to create metal parts and objects, but in recent years there have been great advancements in the techniques and processes used. Improved casting techniques are designed to produce higher-quality results with fewer flaws, greater precision, and improved overall performance.

These improvements have led to reduced costs for production as well as increased efficiency of the entire manufacturing process. In addition, new materials have been developed that allow for more complex designs at lower cost than traditional methods.

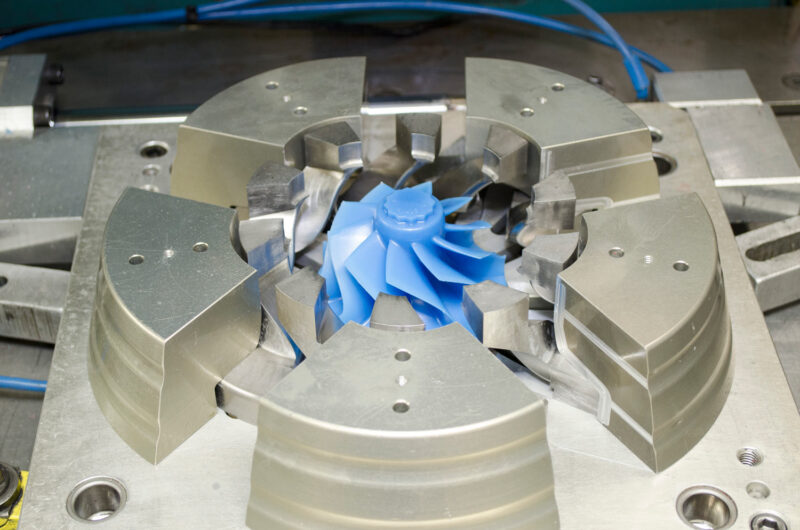

Through these advances all sorts of creative possibilities can now be explored, enabling manufacturers to cast products with intricate shapes which would not have previously been achievable. New horizons are being opened up by these innovations in metal casting – from automotive components made from lightweight alloy metals to medical implants crafted with extreme accuracy – all thanks to the improved technologies available today.

New Alloys and Metals for Casting

The use of new metal alloys and metals for casting has opened up a world of possibilities for the metalcasting industry. The introduction of innovative materials, such as copper-based alloys, nickel-based superalloys and titanium, offer greater mechanical properties and design flexibility than ever before. Additionally, research into alternative production methods that utilize 3D printing technology is yielding even more potential for castings in the future.

With this newfound freedom to create complex parts with unprecedented precision comes increased durability and cost savings that make cast products more competitive than ever before. As these advancements continue to drive innovation in the sector, it is clear that casting will play an important role in ushering in a new era of technological advancement across multiple industries worldwide.

Innovations in Design Technology for Metal Casting

Innovation in design technology for metal casting is rapidly changing the way manufacturing happens. New technologies are allowing manufacturers to more quickly and accurately create products with higher levels of precision than ever before.

With advanced computer-aided design (CAD) software, engineers can visualize their designs onscreen and make changes as needed without having to start from scratch each time. 3D printing has also revolutionized the industry by offering new opportunities for testing out ideas without wasting resources or time in traditional production methods.

Furthermore, advances in robotics have enabled machines that can handle complex tasks such as welding and grinding with greater speed and accuracy than humans could achieve alone. Thanks to these advancements, metal casting no longer requires long lead times or extensive setup costs — manufacturers now have access to faster turnaround times at more competitive prices than ever before!

Conclusion

Metal casting has come a long way in recent years, with new innovations and advancements providing exciting new opportunities for metalworkers. Learn here about the latest technologies that are revolutionizing this ancient art form, from 3D printing to computer-aided design software. With these advances, metal casters can create intricate works of art that were impossible before.

This opens up a world of possibilities for creative expression and improved functionality across multiple industries. The future looks bright for metal casting as these developments continue to push the boundaries of what is possible and open up even more avenues of exploration.